What Is Acrylic?

The term "acrylic" is used for products that contain a substance derived from acrylic acid or a related compound. Most often, it is used to describe a clear, glass-like plastic known as poly(methyl) methacrylate (PMMA). PMMA, also called acrylic glass, has properties that make it a better choice for many products that might otherwise be made of glass. There are two basic types: extruded and cast.

Types

Extruded acrylic is made through a process in which the liquid plastic is pushed through rollers, which press it into sheets as it cools. This is a comparatively inexpensive process, but the resulting sheets are softer than cast acrylic, can scratch easier, and may contain impurities. Extruded acrylic is still generally considered to be good quality, and is usually the more common type made available on the market.

Cell cast acrylic tends of be of higher quality than extruded, but it's also more expensive. In cell casting, single sheets are made by pressing the liquid plastic between pieces of a mold, often made of glass, which is then taken through a gradual heating process. The resulting sheet is stronger than extruded acrylic. This type is often used for aquariums, awards, and other products that require shaping or machining of the final product.

Advantages

Many different products are made from acrylic, including shower doors, bath enclosures, windows, and skylights. It is many times stronger than glass, making it much more impact resistant and therefore safer. Falling against an shower door will not likely break it, for example, and baseballs that crash through glass windows will, in most cases, bounce off acrylic windows. It also insulates better than glass, potentially saving on heating bills.

Acrylic glass is also very clear, allowing 92% of visible light to pass through it. Very thick glass will have a green tint, while acrylic remains clear. It also weathers well, keeping its clarity over the years without turning yellow or breaking down when exposed to sunlight over a long period of time.

Another advantage of acrylic is that it is only half as heavy as glass. This makes this material easier to work with, and makes it a better choice for projects where weight is an issue. It can also be sawed, whereas glass must be scored.

Virtually all major public aquariums now build display tanks out of this thermoplastic, and it is often used in many other buildings. When this material is just over 1 inch thick (about 25 mm), it is bullet resistant; the presidential motorcade, the pope's booth-vehicle, teller enclosures, and drive-through window enclosures all feature bullet-resistant acrylic. It is used for airplane windows as well.

Shaping

A unique property of this thermoplastic is its ability to be shaped. Extruded acrylic is not as strong as cell cast, and tends to crack or splinter when being machined, so most higher quality products are made from cast acrylic. Structures can also be made with no seams, as chemical welding at the molecular level actually "melts" seams into one piece of solid material. Seams that are welded and polished correctly are invisible.

Misconceptions

There are some misconceptions about acrylic, namely that it yellows, turns brittle, and cracks over time. Though this might be true of cheap forms of plastic, it is not so with acrylic. If taken care of, this material can remain new looking for several decades, regardless of age or exposure to sun. Some people worry that it scratches too easily, but unlike glass, scratches may be buffed out.

Compare with glass:

- Glass canisters used to hold cotton balls and other items look great in a bathroom, but for safety reasons, acrylic plexiglass may be a better choice for bathrooms. Transparent acrylic wastebaskets, soap-dishes, and shower curtain rings go with any bathroom color scheme and have a modern appeal.

- Secondly, it weighs 50% less than glass, making it much more portable. Thirdly, acrylic insulates 20% better than glass, which reduces temperature fluctuations and saves on heating and chiller bills.

What Is Acrylic Fabrication?

Acrylic fabrication is the practice of forming a piece of durable plastic into an item. The first step in the process is to make a form or prepare some kind of object that is in the desired shape. Then the acrylic is heated until it is pliable and draped over the object. Once it is in place, the piece is formed with the aid of compressed air and a vacuum. A dye may also be used to help press the piece into shape.

There are several different kinds of tools that can be used for large-scale acrylic fabrication. They include the machining lathe, which is used to cut sheets of plastic, and the milling machine, which moves pieces through the process. There are also polishing machines which use a variety of settings to finish the final product. The process may also include using an annealing machine, which heats the plastic in order to relieve it of stress. Some companies also use a laser machine to cut pieces or to engrave the acrylic.

Depending on the capability of the company, pieces can be made in a wide array of shapes and sizes using the acrylic fabrication process. While small to medium-sized items are for the most part easily attainable, very large pieces are handled by businesses with specialized equipment. As there are so many products that can be made with acrylic fabrication, many companies specialize in a particular area, such as museum display cases.

What Are Lucite® Displays?

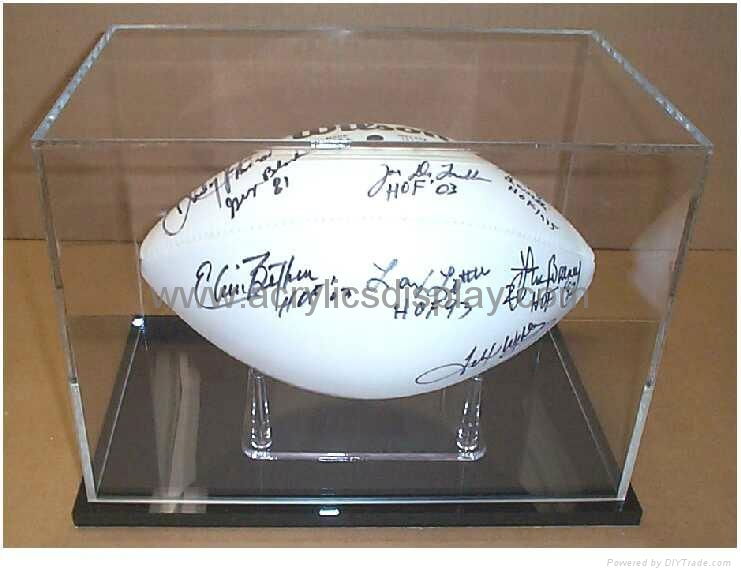

Lucite® displays are products made of a kind of synthetic glass, and are common in many homes and commercial buildings. Lucite® is a sort of hardened acrylic resin; the name Lucite® is a trademark of Lucite International, Inc. It is generically known as polymethyl methacrylate (PMMA). Scientists continue to come up with solutions for using these synthetics to replace traditional silicate glass, where glass might present certain hazards or problems associated with its use. One of these is in commercial or household display items, such as stands, clear containers, as well as trophies and other decorative items.

Many manufacturers use Lucite® as a material for durable displays of all shapes and sizes. Industry professionals can point out aspects of this material that show how well Lucite® displays hold up over time. In general, these displays will not fade or discolor with age. They can stand up to high temperatures as well.

Another benefit of Lucite® displays is that these structures are not prone to cracking or other similar kinds of damage. Scratches can be repaired by professionals, and in general, these items are extremely durable. Thinner Lucite® displays may not be quite as durable or stand up to pressure as well as more solid items.

According to experts, Lucite® is completely inert in its solid form. This is part of what gives these displays; their ability to resist weathering over time. Though the material may not be appropriate for some uses, like microwavable bowls, Lucite® displays are useful in many homes.

Lucite® displays can be useful as jewelry holders, hardware boxes, tackle boxes or other containers for small pieces. They can be good home office containers or storage resources. These sturdy items can also be handy in a bathroom, and are commonly used to hold cosmetic or hygienic items.

Larger displays of Lucite® can be useful in a kitchen to hold food items or utensils. Other displays made out of this material can be made as standing garment racks or other holders for clothes or accessories. Other uses for these larger designs include additional uses for a garage or storage space, for various kinds of hardware like paint cans and paint accessories.

Lucite® displays can be found in just about any room of a house. It is true that there a number similar products made from other materials compete with Lucite®. Nevertheless, displays made from PMMA are still a frequent part of a widely varied catalog of display items.

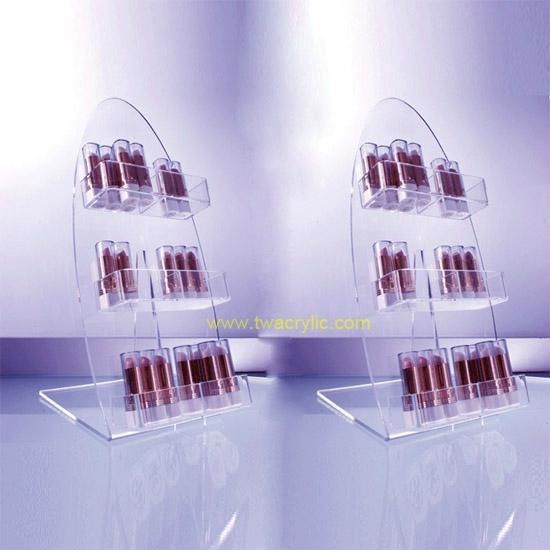

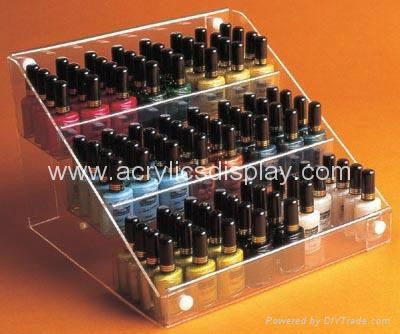

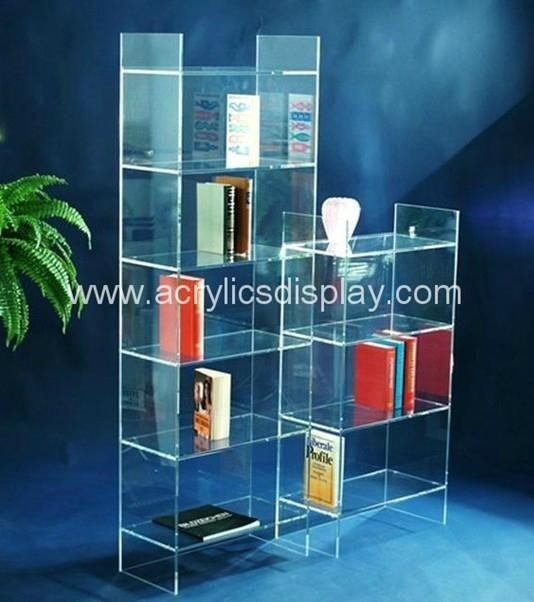

acrylic display stand,acrylic display shelf,

acrylic display,acrylic display cabinet

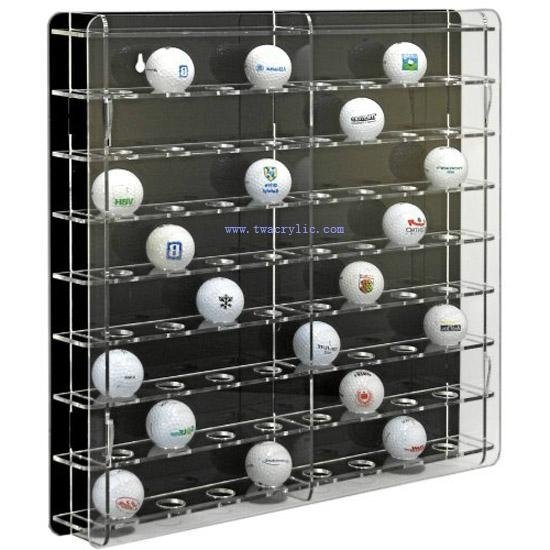

- It’s important to remember that the see-through acrylic clearly highlights your display items because there is no distracting design or color.Acrylic stands are not just limited to business uses or displays for collectibles, and can be used to display just about anything, from rifles to fine china.

- Many types of stores and retail outlets use acrylic stands as fixtures to display the goods and products they have available for consumers to purchase. Acrylic stands are very beneficial because of their durability. Many stores also have a preference for these types of stands because of their stylish and transparent features.

Our factory specialize in acrylic,plexiglass,perspex,lucite,PMMA,

PS,PETG,polycarbon etc plastic products fabrications.

Customized designs are welcomed.

Our product series include:

Acrylic display stand,POP display stand,

POS display stand,acrylic floor display,

acrylic merchandising display,acrylic photo

Frame,acrylic display case,acrylic box,

acrylic sign holder,menu stand,promotion gifts,

cell phone display stands,acrylic coaster,

Jewellery display stand,necklace display,

bracelet display,bangle holder,ring display

stand,eyewear display stands,watch display stand

Counter top display stand,PETG,PVC,

vacuum forming,window display stand,

Acrylic Award,acrylic trophy,acrylic paper weight,

acrylic block,makeup display stand,

acrylic cosmetic display

Our main markets are European and North American,we also have some customers

from the Asia,Middle East and African etc.

The customers are ranging from large corporations to private individuals.

Our teams have an intimate knowledge of acrylic products to understand your technical needs and develop

affordable and attractive solutions.

If any ideas or just draft drawings of acrylic products, please contact us freely.

Email: info@acrylicsdisplay.com

Alibaba website: http://topwisdom.en.alibaba.com

The main processing procedure include:

- cut to size,laser engraving

- heat bent to shape,diamond polishing,buffing,milling etc

- beveled edges,no mark gluing,sandblasting

- silk screen printing,spray painting etc

- clean and safe package.

Acrylic display stands are an option for displaying items in a retail store, exhibiting your collectibles at home or otherwise displaying items with high visibility. Our factory can produce wide varieties of shapes and styles such as open, tiered stands, table displays and shelving. We can build your own acrylic display to custom specifications.

When making acrylic display boxes, the key fabrication is to make sure no glue mark.

Use a tape to attach 5 of the 6 Plexiglas pieces into 4 walls and a cover. Just use 2 pieces of tape on each side after gluing them. The glue we use will wick beneath the seam in between the Plexiglas pieces so we will cover the whole seam with tape so the glue will not mess up the display case, thus affecting the physical appearance or aesthetic appeal of the acrylic display case.

Plastic is an attractive and versatile material that you can use in many ways. It is shatterproof, strong, lightweight, durable, easy to cut, and it comes in different colors. Acrylic is an obvious and wonderful option to use in display cases, storage containers, bookshelves, and other various shelving needs.

Acrylic display cases protect valuable objects while offering a complete view of the items within. Acrylic is a practical alternative to glass because of its greater impact resistance. Acrylic is lighter than glass and can easily be cut. Because acrylic panels can be glued together, it's an ideal material for transparent cabinets.

They can be used not only in stores but also in offices.

Nowadays, more and more people are utilizing acrylic display stands and display cases at home.

They are available in many different designs with many different purposes.

Display stands can be one of the best multi-purpose features for your home and office.

We are specialize in acrylic display stands etc fabrications, and we have many years of experience and an excellent knowledge of acrylic material and processing. Acrylic are also called plexiglass or perspex or PMMA.

As manufacturers we are in complete control of everything we do. This means we can offer a design service tailored to your needs and can react quickly to your ideas and feedback, without being dependent on a third party.

The company has built itself an excellent reputation for perfecting high standards and pride ourselves in the quality of our products and designs.

Top Wisdom Group Ltd has a large range of clients ranging from private individuals looking for high quality items for their home through to large corporate companies. We are happy to make perfect quality acrylic display stands,acrylic display cases for the retail industry.